Die Casting Composite Processing

Drilling, milling, tapping, grinding with machining accuracy less than 20μm

Applications

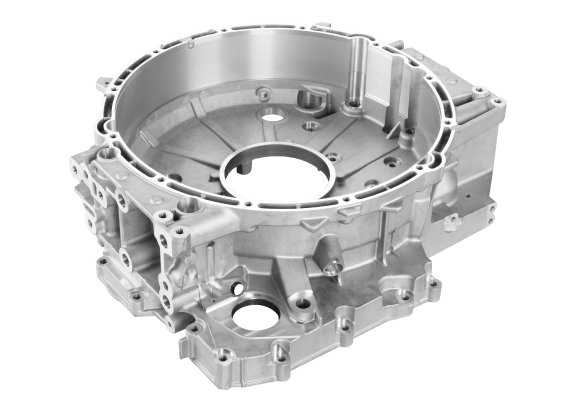

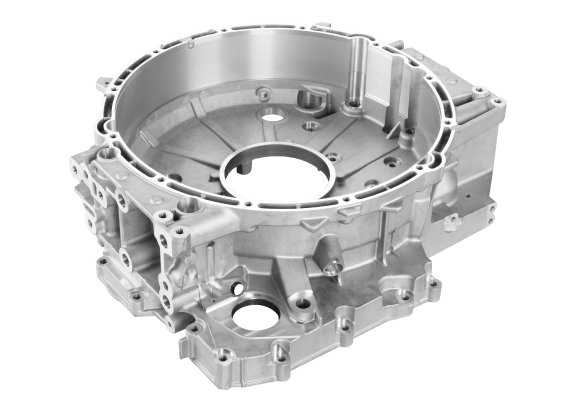

Flywheel Housing Die Casting

+ JINGDIAO 5-axis high-speed machining center completes positioning machining with one clamping;

+ The number of tools used for machining reaches 51;

+ Adopt milling, boring, drilling, tapping, reaming and other machining methods.

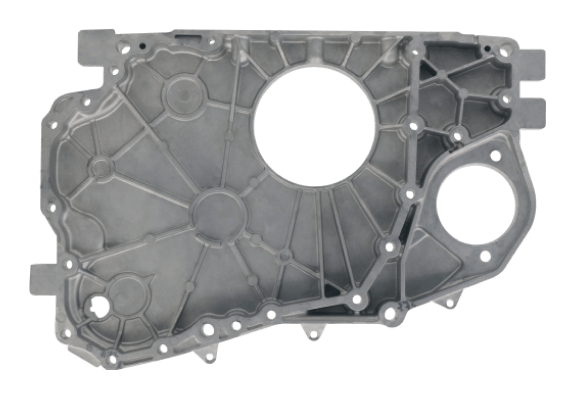

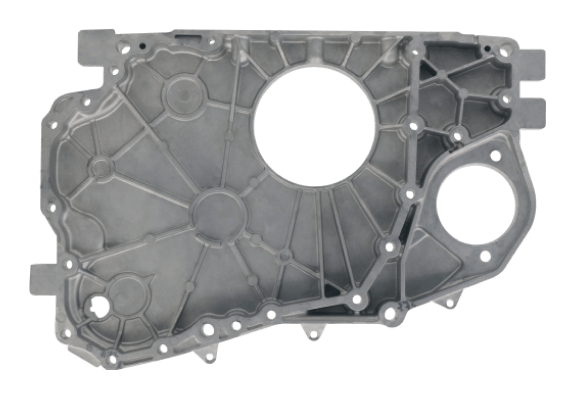

Gear Cover Die Casting

+ The distance error between the key machining surface and the datum surface is less than 0.1mm;

+ Use JINGDIAO on machine inspection technology to align blank quickly and realize small batch production;

+ JINGDIAO 5-axis high-speed machining center completes positioning machining with one clamping;

+ Adopt milling, boring, drilling, tapping, reaming and other machining methods;

+ Cycle time is 22min.

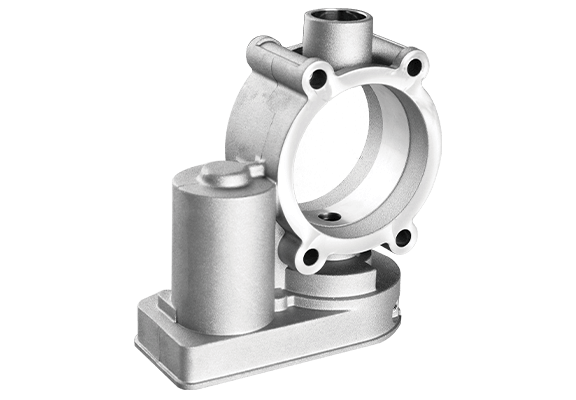

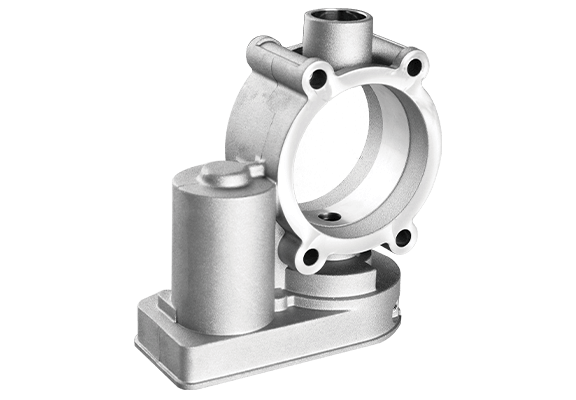

Throttle Die Casting

+ The hole coaxiality is less than 0.01mm,the reaming roughness Ra≤0.2μm;

+ The yield rate is up to 98%.

Flywheel Housing Die Casting

+ JINGDIAO 5-axis high-speed machining center completes positioning machining with one clamping;

+ The number of tools used for machining reaches 51;

+ Adopt milling, boring, drilling, tapping, reaming and other machining methods.

Gear Cover Die Casting

+ The distance error between the key machining surface and the datum surface is less than 0.1mm;

+ JINGDIAO 5-axis high-speed machining center completes positioning machining with one clamping;

+ Adopt milling, boring, drilling, tapping, reaming and other machining methods;

+ Cycle time is 22min.

Throttle Die Casting

+ The hole coaxiality is less than 0.01mm,the reaming roughness Ra≤0.2μm;

+ The yield rate is up to 98%.

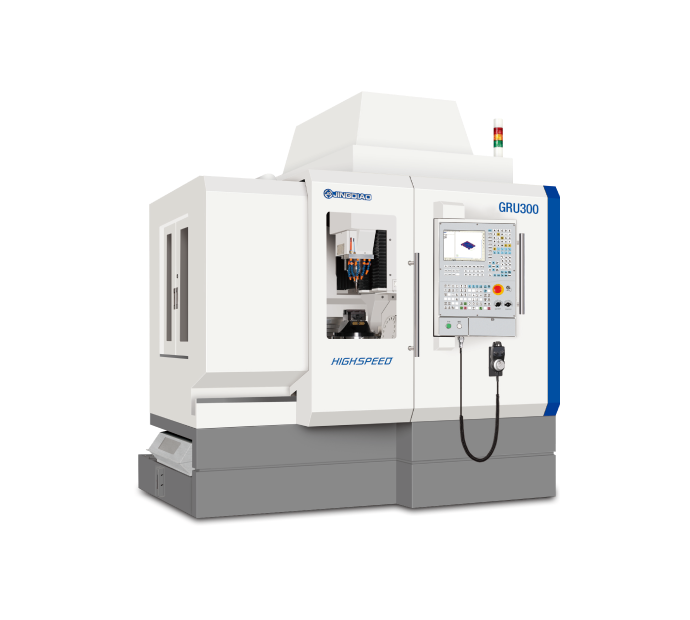

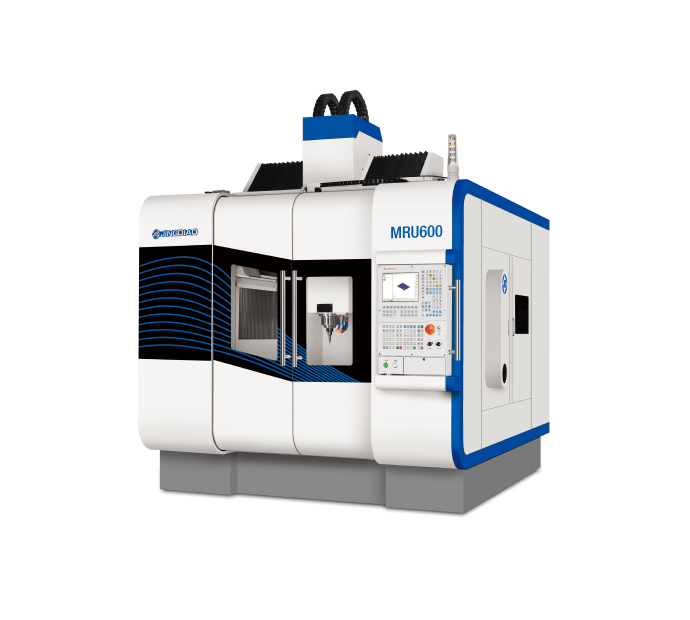

Select the Suitable Machine Based on the Shape and the Size of Parts

JINGDIAO 5-axis high-speed machining center is equipped with JINGDIAO spindle, which has large torque and can meet the processing needs of large cutting volume with different tools,

therefore drilling, milling, boring and grinding of die casting is possible.

Key Configuration

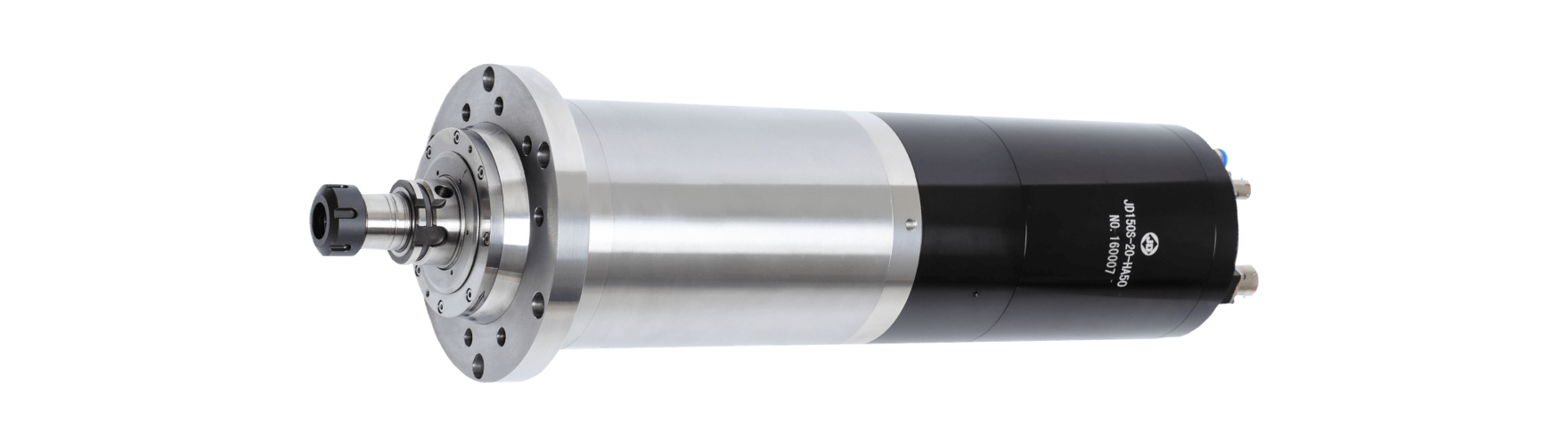

High Precision Spindle with Composite Processing Ability

Capable of milling, drilling, tapping, boring, reaming and grinding

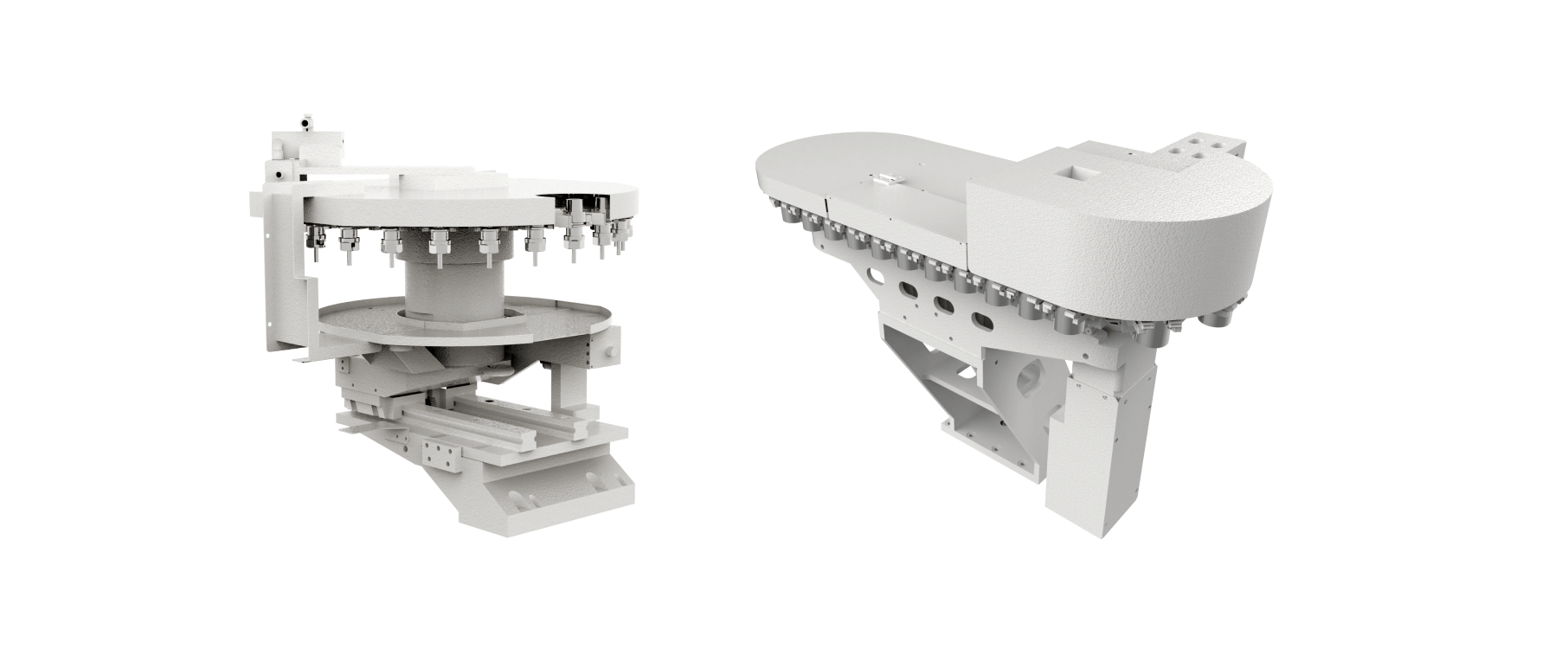

Meet the Needs of Cutting Tools for Complex Parts Processing

Chain type, disc type and other large capacity tool magazine can be selected to meet the use of combined tools and special tools in composite machining.

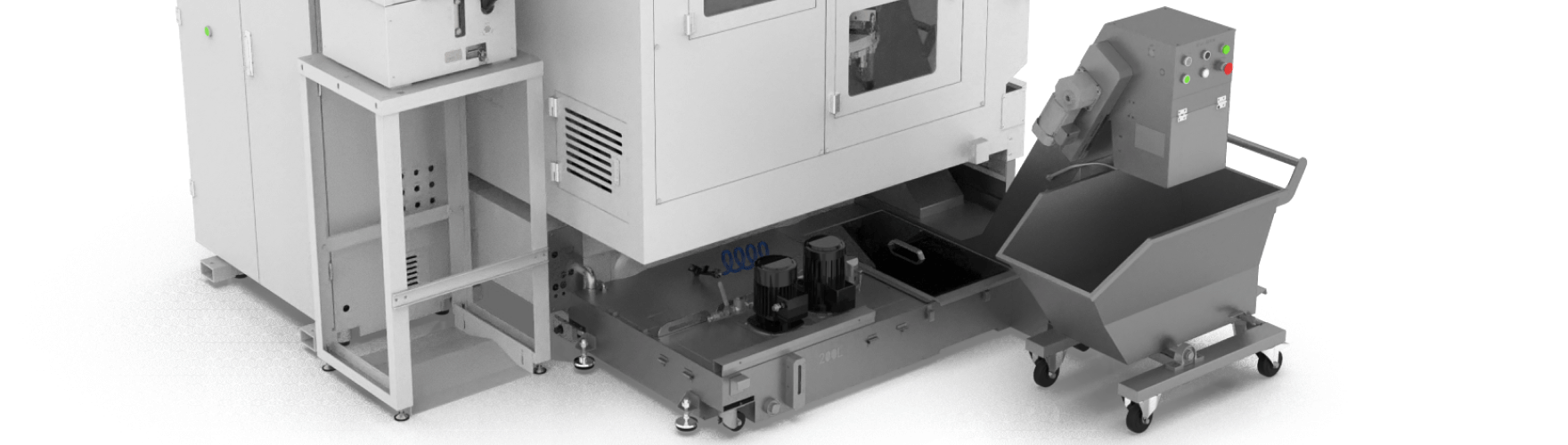

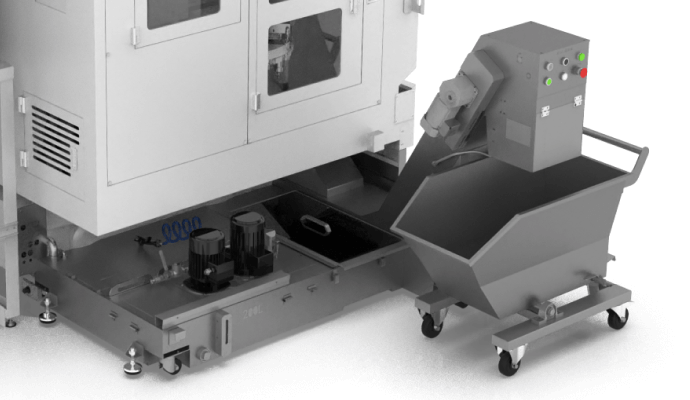

Chip Disposal System of Machine Tool

The chip disposal system has perfect performance, including internal spray, internal spiral chip conveyor and external scraper chip conveyor, etc. They can realize efficient chip disposal in the processing and greatly reduce the frequency of manual cleaning of waste.

JINGDIAO Proven Precision Machining Solutions

Because of the large discreteness of die casting parts’ accuracy, the alignment of die casting parts often needs manual work, which will affect the continuous processing of machine tools.

To solve this problem, JINGDIAO uses on-machine inspection system to align every die casting part automatically and compensate the error intelligently, thus ensures the accuracy and efficiency of workpiece alignment, and realizes the work mode of "in machine automation".

Contact us right now and introduce “in machine automation” work mode to your workshop to improve the processing yield rate and efficiency.