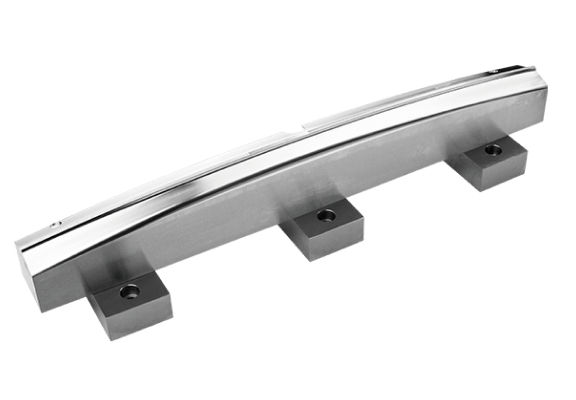

Mirror Mold Parts Polishing

The Surface Accuracy Reaches Micron Level and the Surface Roughness is Less than 10 nm with Mirror Effect.

Applications

Select the Suitable Machine Based on the Shape and the Size of Parts

Mirror-finished surface with a profile accuracy less than 10μm needs dozens of hours of grinding and polishing. Therefore, it is very important to choose a machine with high basic accuracy and good thermal stability.

GRU200

JINGDIAO 5-Axis High-Speed Machining Center

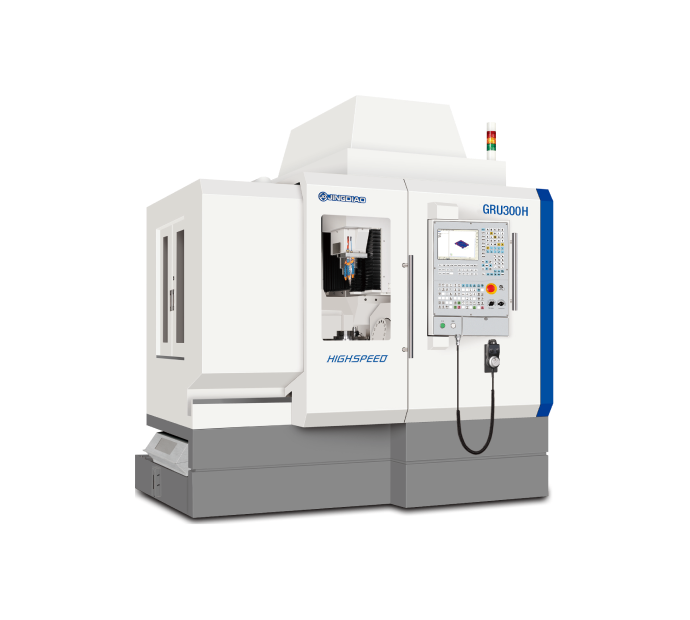

GRU300H

JINGDIAO 5-Axis High-Speed Machining Center

GRU400

JINGDIAO 5-Axis High-Speed Machining Center

JINGDIAO Proven Precision Machining Solutions

To realize long-time mirror grinding and polishing, the importance of machine tools and application is equal. The core of application is to control the small changes of key elements in the process of precision grinding and polishing, such as tools, workpieces, etc.

JINGDIAO's proven mirror mold parts grinding and polishing solution can use small-size PCD tools to stably grind and polish for more than 80 hours on the precision type JINGDIAO 5-axis high-speed machining center, and finally make the mold surface accuracy reach micron level and the surface roughness reach nano level.