GRU300H

Machining Center for Mirror Machining is Applicable to the Processing of Mirror Mold Parts with High Surface Quality and High Precision Requirements in 3C Consumer Products, Medical Treatment, Optics, Automotive Electronics and Other Industries.

Equipped with spindle for precision machining, PCD tool can be used for long-term stable grinding and polishing.

Stable realization of 2 ~ 10 μm machining accuracy, surface roughness below 10nm.

- X/Y/Z Travel: 390/510/300 mm

- A/C Rotation Range: -110°~90°/ 360°

- Worktable Size: Ф300mm

- Max. Load: 100kg

-

Spindle Type:

Spindle for Precision Machining

JD135E-32-HE32/F - Spindle Specification: 32000rpm/HSK-E32

- Tool Magazine: Umbrella Type(24 Tools)

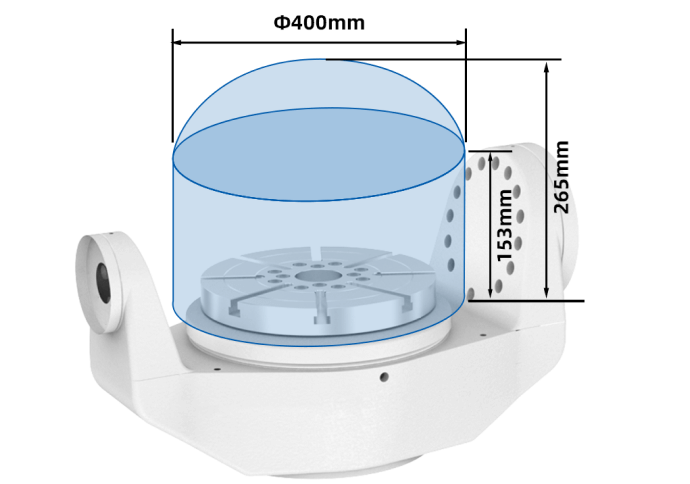

Max. Workpiece Dimension Unit: mm

Max. Workpiece Dimension Unit: mm

- X/Y/Z Travel: 390/510/300 mm

- A/C Rotation Range: -110°~90°/ 360°

- Worktable Size: Ф300mm

- Max. Load: 100kg

-

Spindle Type:

Spindle for Precision Machining

JD135E-32-HE32/F - Spindle Specification: 32000rpm/HSK-E32

- Tool Magazine: Umbrella Type(24 Tools)

Highlights

Mirror Machining with High Surface Quality and High Precision

Achieve “0.1 μm feed, 1 μm cutting, nanoscale surface roughness” machining stably;

It can realize the machining of precision mold parts with machining accuracy less than 10 microns and surface roughness less than 10 nanometers;

Equipped with spindle for precision machining with high speed and low vibration, it can meet the stable grinding and polishing of PCD tools for a long time and realize the effect of curved surface mirror effect.

Stable Machining Quality

MOL system can be configured to effectively control the temperature in the machine tool and reduce the impact of temperature fluctuation on accuracy;

JINGDIAO on-machine inspection system can be used to quantify the state of machine tools, tools and workpieces in precision machining;

Configure SurfMill software, the management platform of JINGDIAO precision machining, and output complete NC machining programs, including machining, inspection and control programs.