GRU500

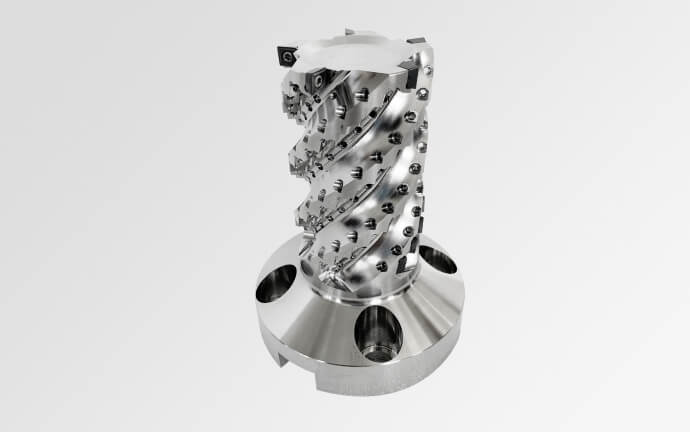

Precision Type JINGDIAO 5-Axis Machining Center Suitable for Drilling, Milling and Grinding Composite Machining of Complex Metal Hard Materials (HRC > 50).

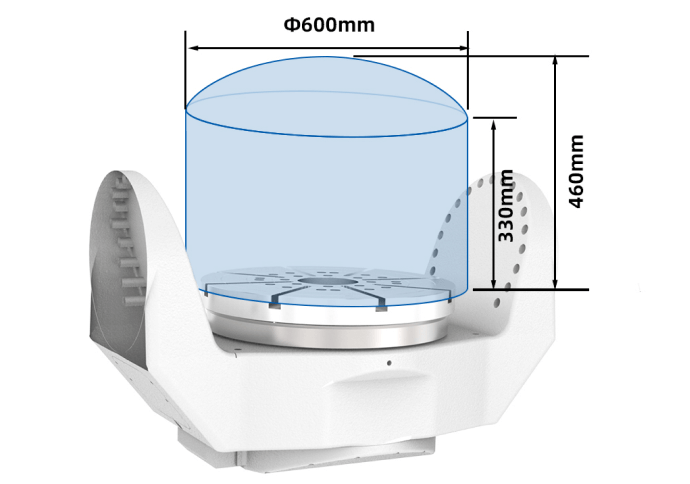

- X/Y/Z Travel: 550/770/450mm

- A/C Rotation Range: -115°~ +90°/360°

- Worktable Size: Ф500mm

- Workload: 300kg

Max. Workpiece Dimension Unit: mm

Max. Workpiece Dimension Unit: mm

- X/Y/Z Travel: 550/770/450mm

- A/C Rotation Range: -115°~ +90°/360°

- Worktable Size: Ф500mm

- Workload: 300kg

JD150S-20-HA50/C Coolant through Spindle

JD150SC-20-HA50/A High-Speed Precision Spindle

JD180S-15-HA63/B Coolant through Spindle

JD180SC-15-HA63/B

JD150S-20-HA50/C Coolant through Spindle

JD150SC-20-HA50/A

JD180S-15-HA63/B Coolant through Spindle

JD180SC-15-HA63/B

Highlights

The Actual Working Conditions be Fully Considered in the Design

Both axis A and axis C of the turntable adopt double drive technology, with a maximum load of 300kg;

Rear side door at the back of the machine tool is reserved, makes it convenient to arrange automatic loading and unloading device, and realize automatic machining;

The top door can be opened, and makes it convenient for loading and unloading heavy workpieces.

Excellent Composite Processing Ability

Equipped with high-speed precision spindle as standard, torque up to 21.5Nm, it can do drilling, tapping, grinding, polishing, high light milling, etc;

Equipped with internal spray system and internal screw chip conveyor as standard, cooperate with external scraper chip conveyor, it can dispose chips rapidly;

63-tools large capacity chain type tool magazine is optional to meet diversified processing needs;

Coolant through spindle is optional, which is suitable for deep hole and deep cavity processing.

Stable Processing Quality

Achieve “0.1 μm feed, 1 μm cutting, nano surface roughness” machining effect stably;

Equipped with JINGDIAO on machine inspection system to quantify the status of machine, tools and workpieces in precision machining;

Equipped with MQL to control the temperature in the machine tool and reduce the influence of temperature fluctuation on accuracy effectively.