GRU300

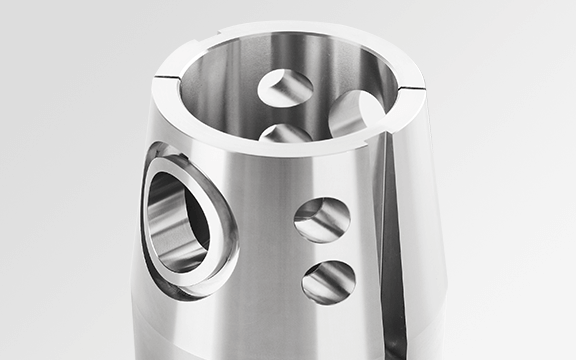

Precision Type JINGDIAO 5-Axis High-Speed Machining Center Suitable for Precision Machining Such as Drilling, Milling and Grinding of Complex Shape Metal Hard Materials (HRC > 50) and Precision Die Mold Parts Machining with High Surface Quality Requirements.

JINGDIAO high-speed precision spindle with torque of 21.5Nm is a standard component to meet the needs of a wide range of tools.

- X/Y/Z Travel: 390/510/300 mm

- A/C Rotation Range: -110°~90°/ 360°

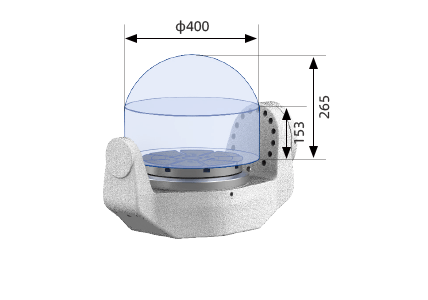

- Worktable Size: Ф300mm

- Max. Load: 100kg

Max. Workpiece Dimension Unit: mm

Max. Workpiece Dimension Unit: mm

- X/Y/Z Travel: 390/510/300 mm

- A/C Rotation Range: -110°~90°/ 360°

- Worktable Size: Ф300mm

- Max. Load: 100kg

JD135E-32-HE32/F High-Speed Precision Spindle

JD150S-20-HA50/C Coolant through Spindle

JD150SC-20-HA50/A

Highlights

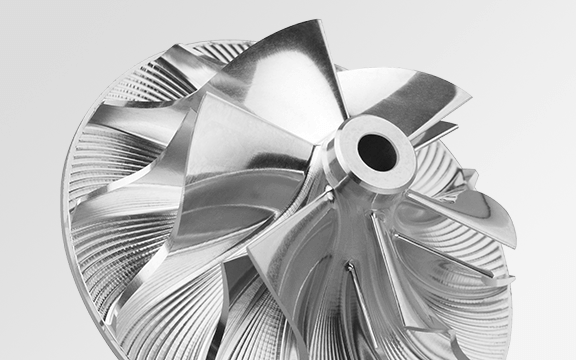

Applicable to Multiple Machining Fields

--Precision machining, precision mold machining, precision grinding

Achieve “0.1 μm feed, 1 μm cutting, nanoscale surface roughness” machining stably;

JINGDIAO high-speed precision spindle is equipped as standard, and the torque is up to 21.5nm, which can meet the needs of a wide range of tools in precision mold machining. Such us, large-diameter face milling cutter is used for large surface finish machining of die;

JINGDIAO spindle for precision machining is optional to machine the mirror-finished surface;

Coolant through spindle is optional, which is suitable for deep hole and deep cavity processing.

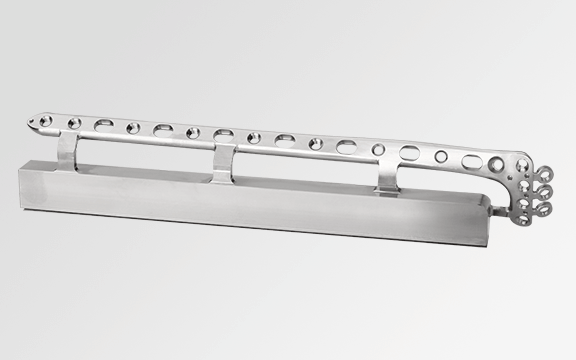

Applicable to Multiple Machining Fields

--Batch machining of metal parts

JINGDIAO high-speed precision spindle is equipped as standard, which can achieve composite processing such as milling, grinding, drilling, boring and tapping;

The JINGDIAO high-speed precision spindle is used for side milling and cycloid machining to ensure the machining efficiency;

The in-machine spray system can be installed to cooperate with the screw chip conveyor in the machine to quickly clean the chips in the machine;

Scraper style chip conveyor can be equipped to collect a large amount of chips to the chip collecting trolley, so as to prolong the chip cleaning cycle for parts batch machining.

Stable Machining Quality

JINGDIAO on-machine inspection system can be used to quantify the state of machine tools, tools and workpieces in precision machining.