VIRTUAL PROCESSING

Do the Entire Multi-axis Machining on Your Computer

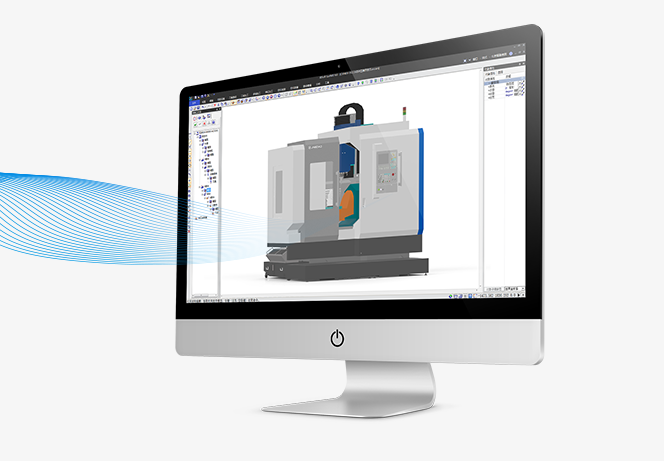

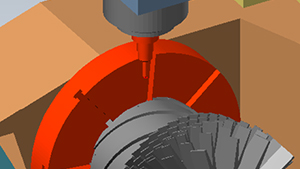

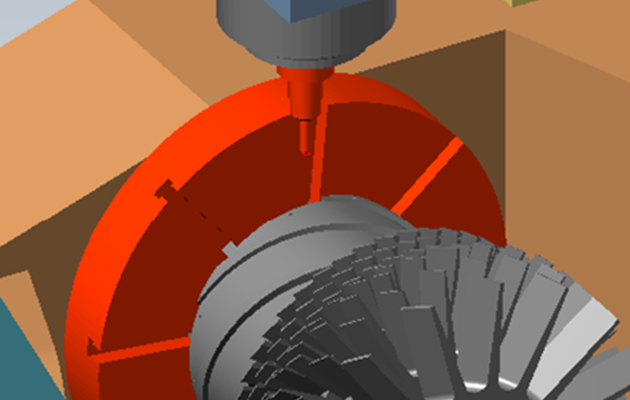

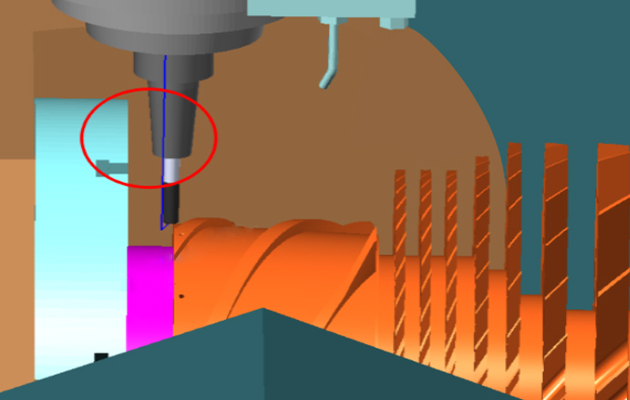

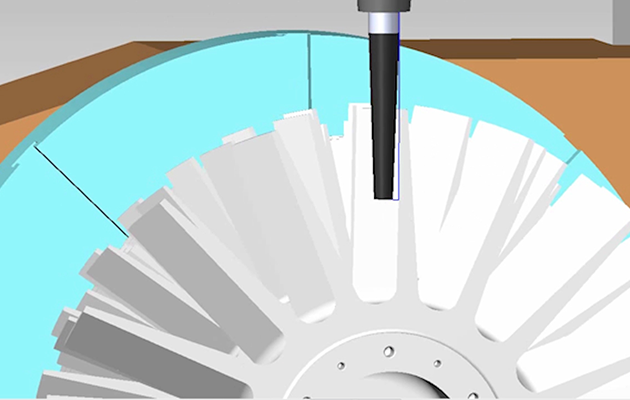

In 5-axis machining, the movement of machine tools is complicated, and the machining process is not intuitive and difficult to predict collisions between spindle and fixture, spindle and rotary table, tool holder and workpiece. Jingdiao virtual processing technology constructs the same digital scene in CAD/CAM software, simulating the entire process and eliminates the risk of collision at programming stage to guarantee the safety of 5-axis machining.

FEATURES

FEATURES

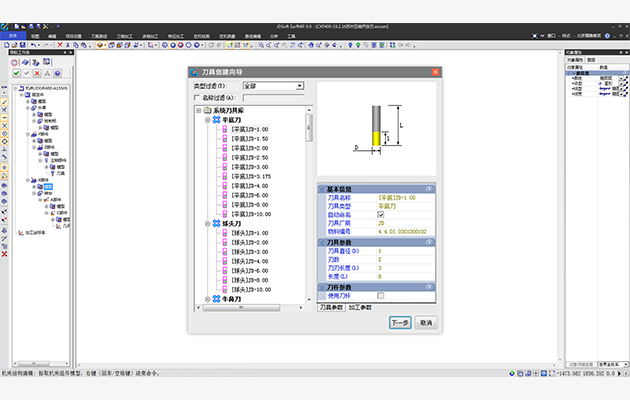

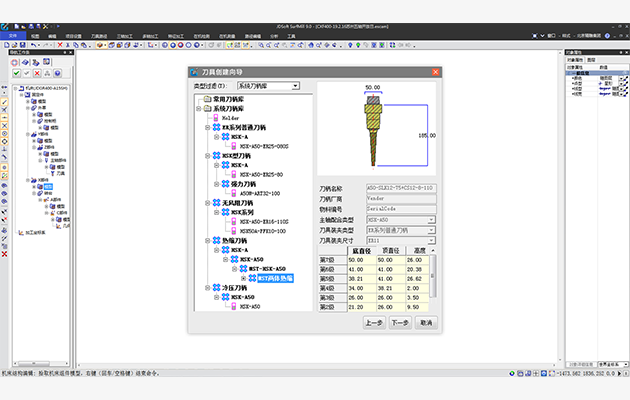

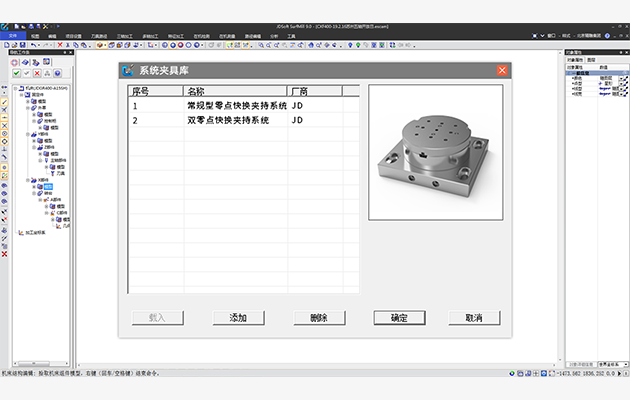

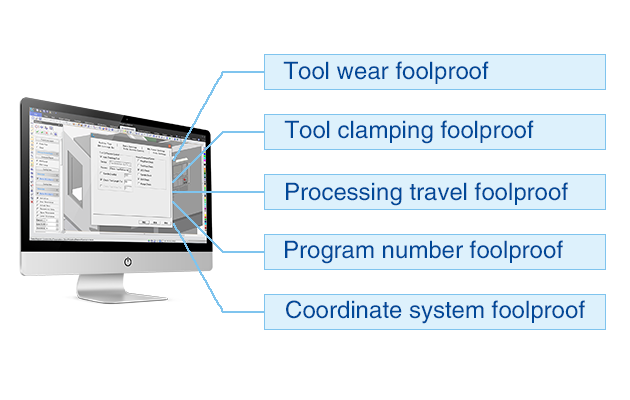

Digitization of machining factors

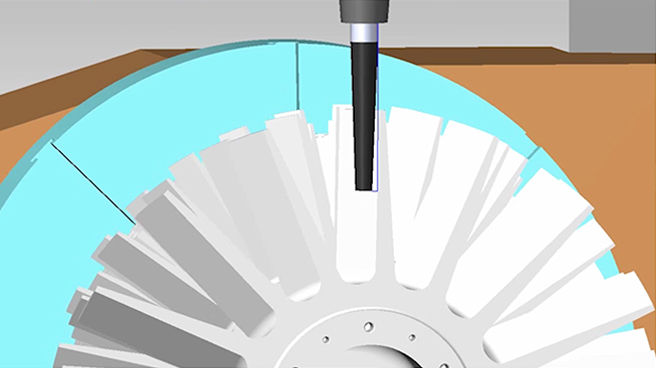

Actual Environmen

Software Side

Avoidance of collisions due to exact same virtual machining environment as real world

Actual Environmen

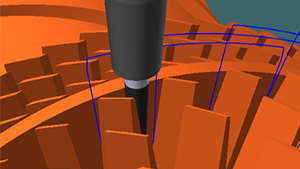

Process optimization in software

Risks

Optimization/p>

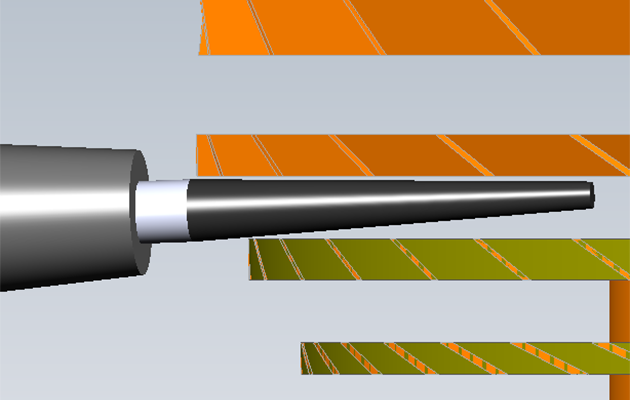

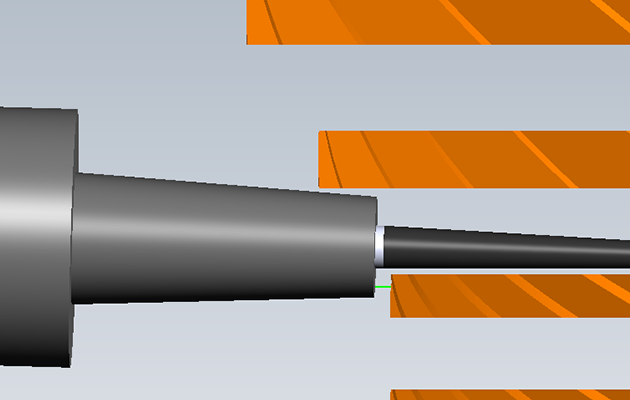

Whole process simulation

Simulation

Actual Process

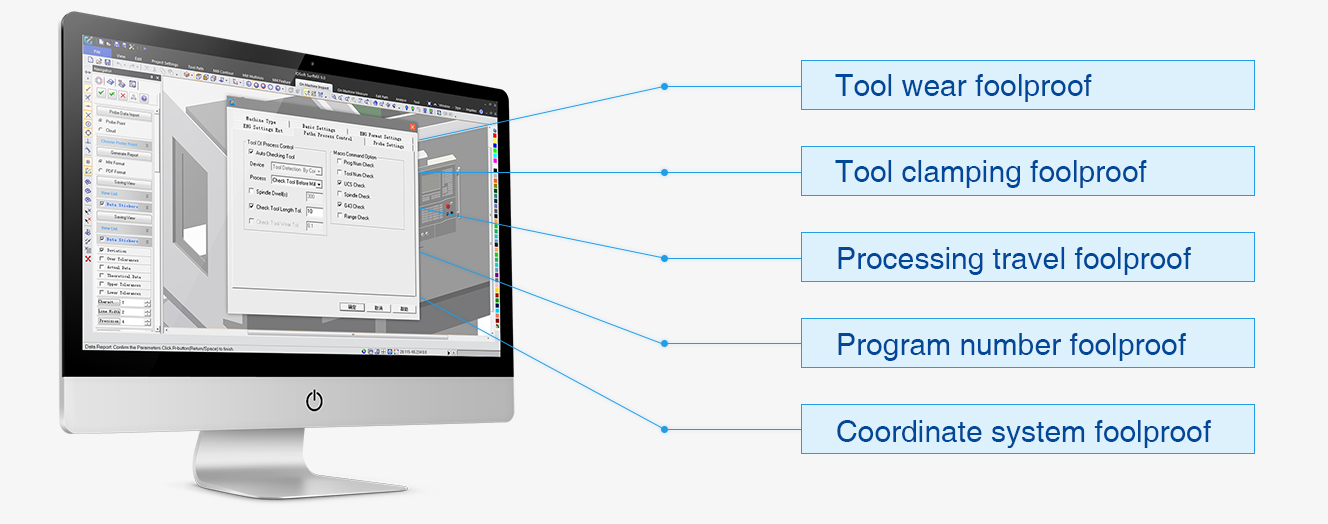

NC output foolproof

Path Process Control

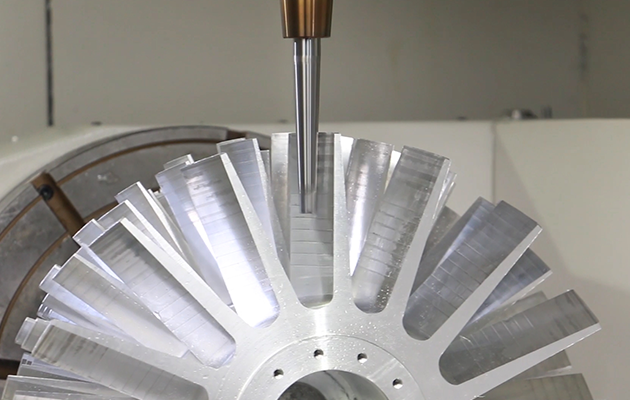

Application

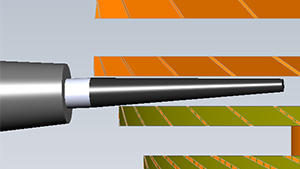

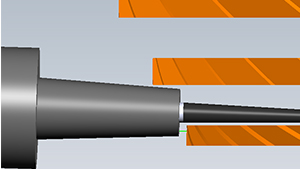

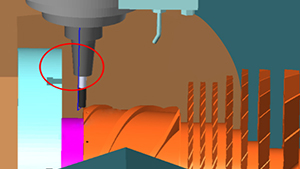

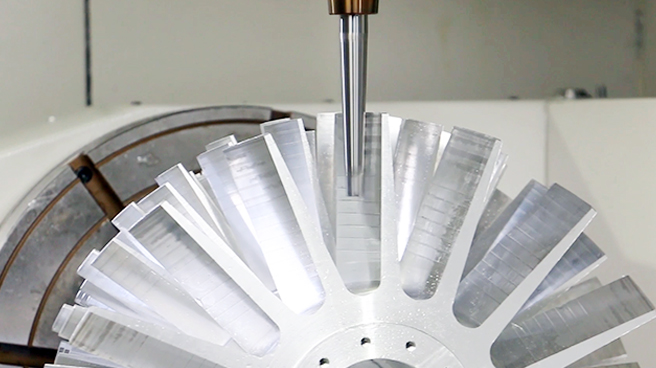

Size: Ø350×286mm Material: 7075-T6 Al Cycle Time: 16h

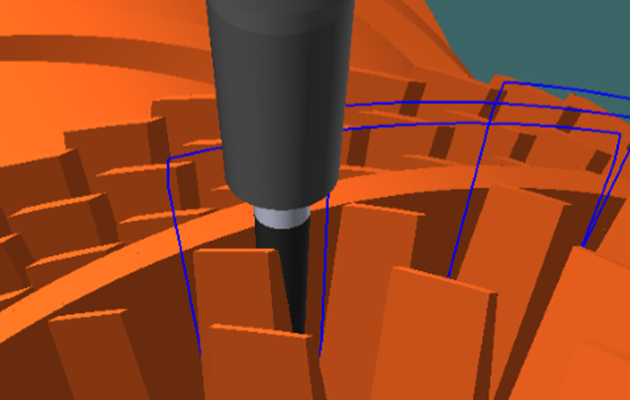

249 blades machined

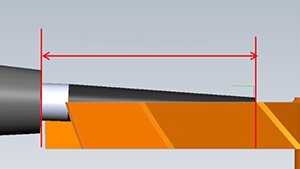

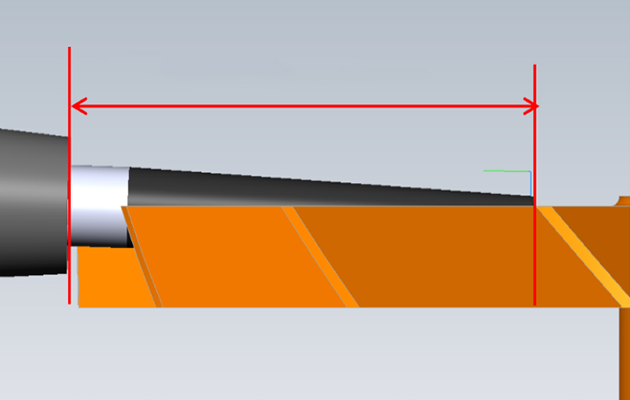

Length diameter ratio of tools reach 14:1

Closest distance between bottom of tool holder and blade is 1mm

Dynamic imbalance < 0.6gmm