AUTOMATION SOLUTION FOR ELECTRODE

Organize Electrode Production Rapidly and Flexibly

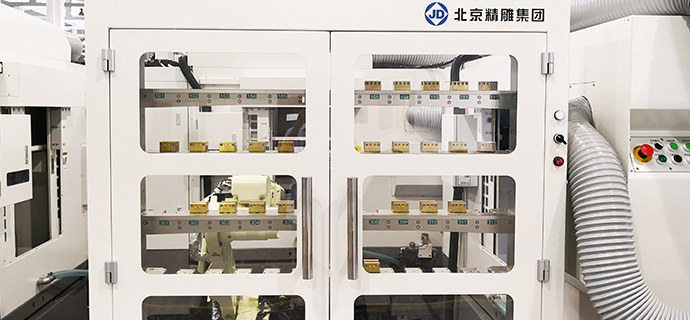

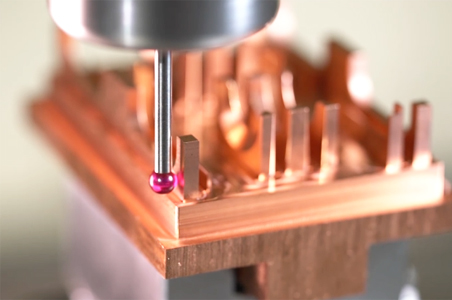

Multi-variety and small batch is a very common production mode for electrode processing, which has high requirements on whether to achieve flexible production change. Besides, unable to count working hours, hard to control quality, and information isolated islands also happen. In response to these problems, we developed electrode automation solution, which can not only realize automation, informatization of electrode production, but can help you organize production and enter production status in a short time so that the whole management can be flexible and efficient.

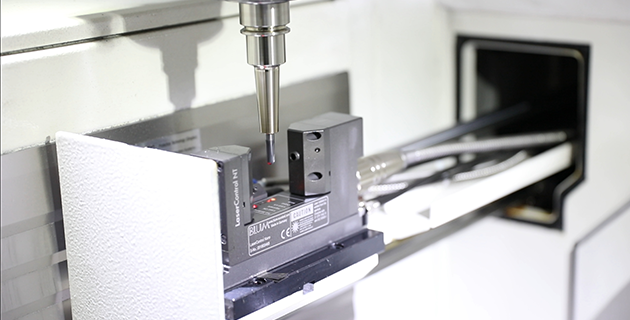

Jingdiao High-speed machining center

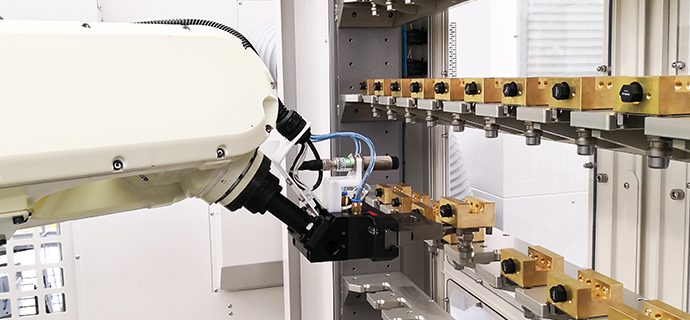

Flexible Solutions for Different Production Links

Production Organization Flexibility

To respond to production rapidly and enter production mode in a short time, you need this solution. It can help you organize and arrange production tasks flexibly and reduce the impact of material instability. You won’t be bothered by problem of production management any more, which is caused by irregular and discontinuous supply of material, staff mobilization, scheduling, day and night shift.

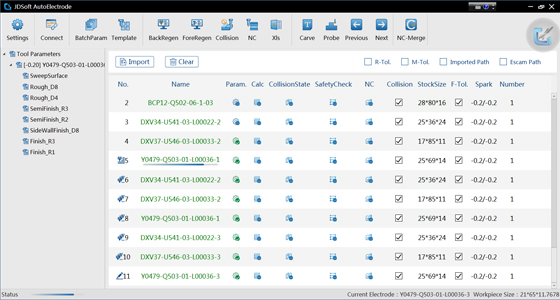

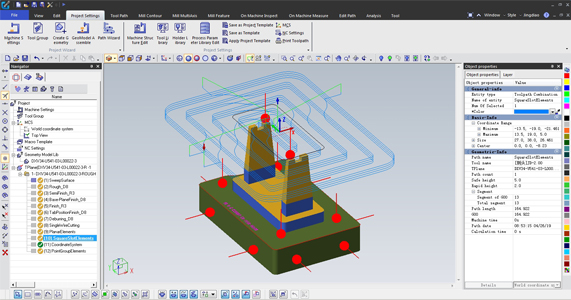

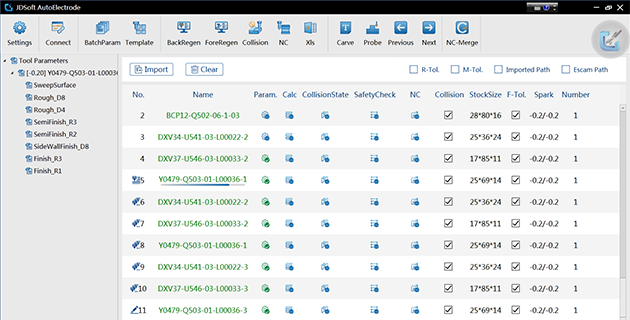

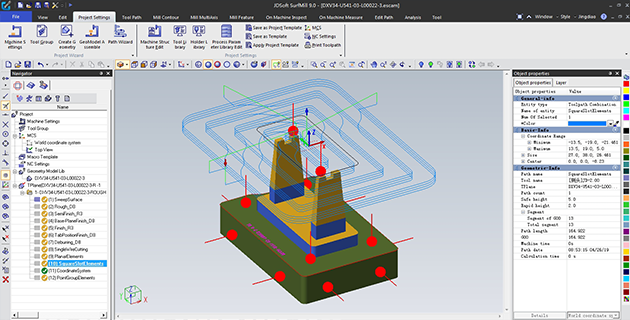

Convenient and Efficient Program

Process programming is an important and time-consuming part of production preparation. If program cannot be completed and imported into machine tools in time, continuity of electrode production will be seriously affected. JDSoft AutoElectrode is targeted to improve programming efficiency through functions such as automatic recognition of workpiece features, automatic calculation, program template, batch programming and batch importing. These functions will make program preparation convenient and solve the problem that the processing program cannot be in place in time.

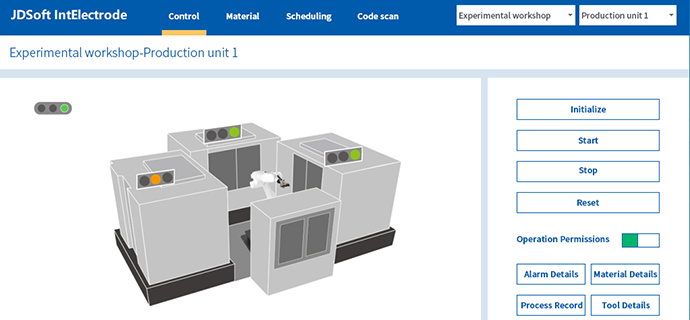

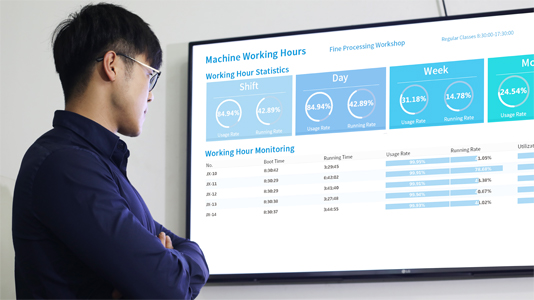

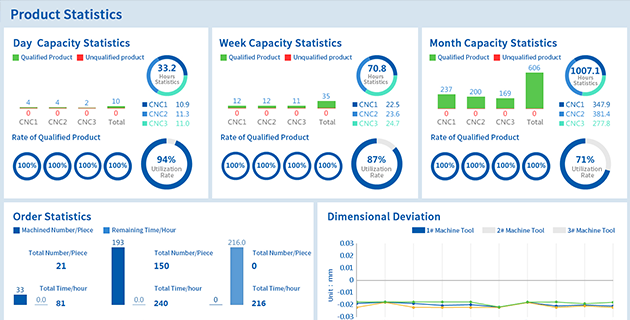

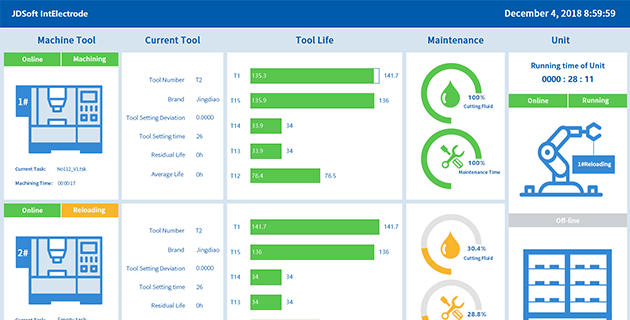

Informatization of Production and Operation Status

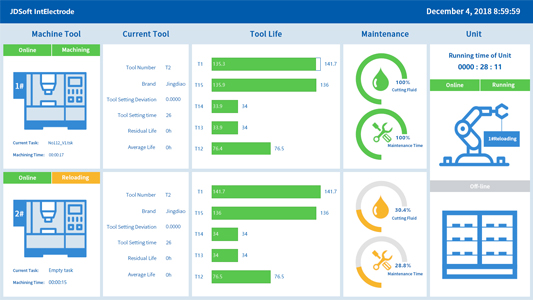

Knowing the operation conditions and production schedules in real time is necessary for a workshop manager, because it means a precise management of the whole production and can deal with problems quickly if the alarm is triggered.

JDSoft IntElectrode, an automation cell management software, helps workshop manager manage production and material, monitor equipment and live-action. It also integrates several modules such as file and task management, alarm analysis and processing statistics. The on-site manager will know the operation status of each link, receive alarm immediately and solve problems, and maintain production factors as needed.

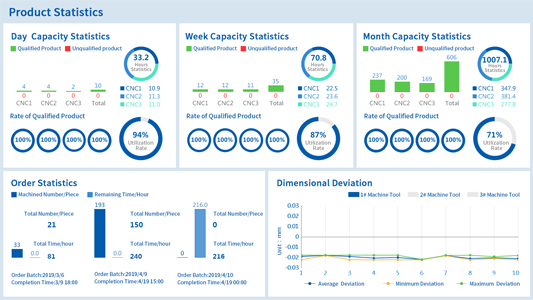

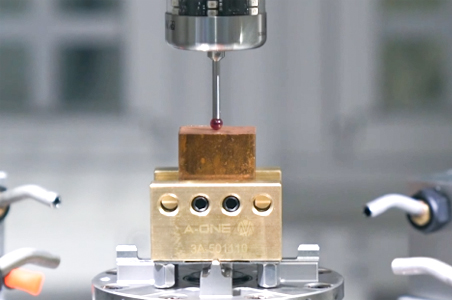

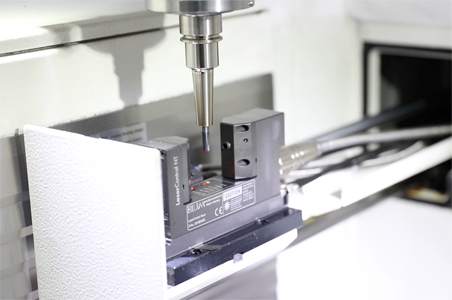

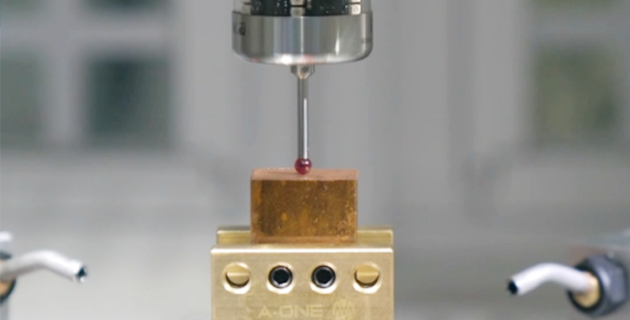

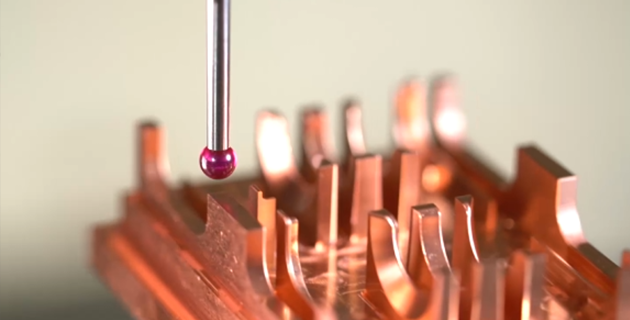

Systematization of Quality Control

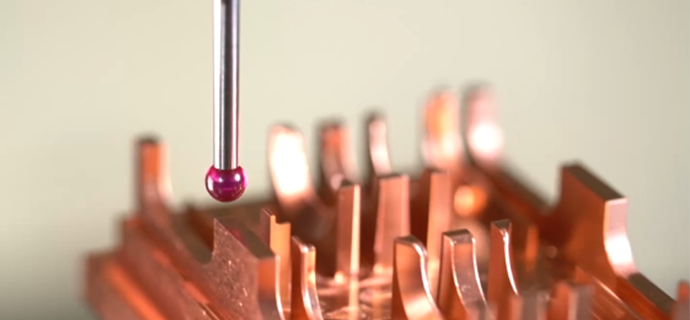

By introducing OMIM technology into automation solution, material foolproof, originating, tool wear detection and finished product measurement can be done on machine. For finished product which is usually measured off line in current production mode, measuring efficiency may be influenced due to lack of CMM. But, OMIM can realize quality control of each product on machine and unqualified product will be moved into silo automatically. This method can optimize product QC and improve processing continuity.

”2+22” Operation Mode

With all the functions provided for staff from different positions in production, “2+22” production mode is generated which is quite different from current electrode production mode. “2” means 2 hours spent on inspection before production, including tool loading/changing, blank replacement, programming, chip cleaning, health self-inspection, etc. 22 hours is the actual production time. By routing production processes and standardizing on-site operation, the equipment utilization rate can be effectively improved, and the advantages of this solution can be maximized.