HGU600

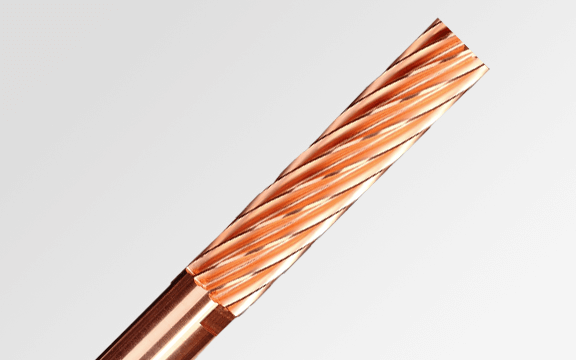

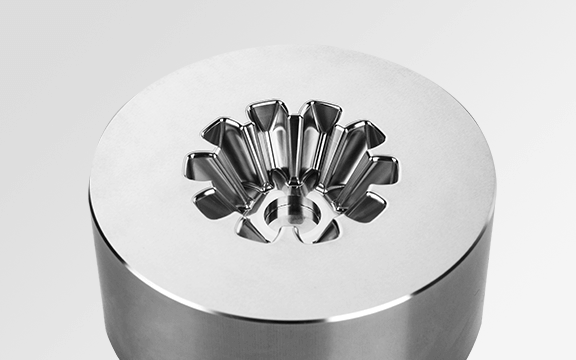

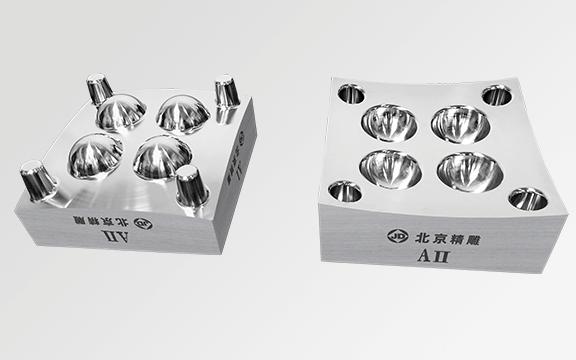

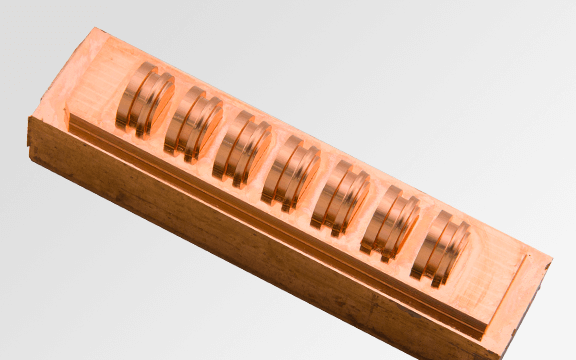

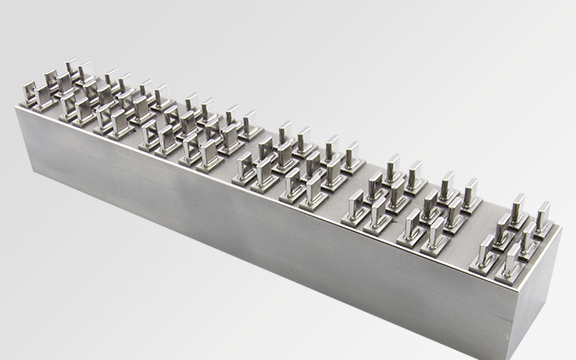

3-Axis High-Speed Machining Center, Suitable for Milling Machining of Micron Scale Electrode, Precision Mold Parts and Precision Hole Grinding of Metal and Special Materials.

It can realize 2 ~ 5 μm machining accuracy stably with reasonable software and hardware configuration.

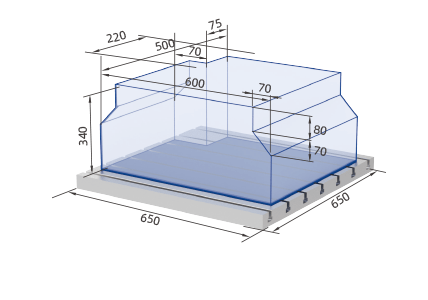

- X/Y/Z Travel: 600/500/300mm

- Worktable Size: 650×650mm

- Max. Load: 300kg

Max. Workpiece Dimension Unit: mm

Max. Workpiece Dimension Unit: mm

- X/Y/Z Travel: 600/500/300mm

- Worktable Size: 650×650mm

- Max. Load: 300kg

JD135E-32-HE32/F

Highlights

Stably Realize Micron Scale Machining

The full closed-loop control system is adopted to ensure the motion accuracy of the machine tool;

JINGDIAO high-speed precision spindle with a maximum speed of 32,000rpm can be selected;

It can be configured with JINGDIAO on-machine inspection system is optional to quantify the state of machine tools, tools and workpieces in precision machining.

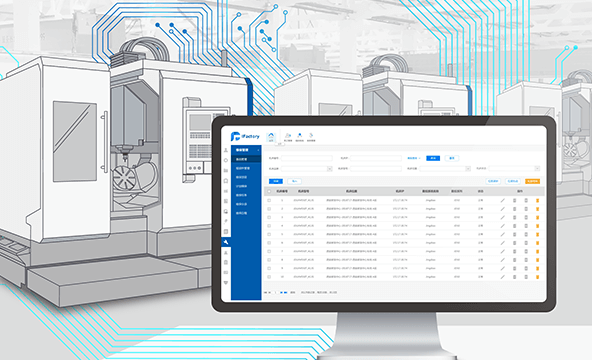

Multiple Configuration Options to Meet Different Production Needs

It can be equipped with various models of JINGDIAO spindles and tool magazines are optional, to meet the needs of different processing scenes;

It can be equipped with various models of precision rotary table are optional to expand the multi axis processing mode.

Integrate JINGDIAO characteristic technology to ensure precision machining quality

JINGDIAO on-machine inspection system can be used to quantify the state of machine tools, tools and workpieces in precision machining.