HGU400

3-Axis High-Speed Machining Center, Suitable for Milling Micron Precision Electrode, Precision Die Parts and Grinding Precision Holes in Metal and Special Materials.

Realize 2 ~ 5μm machining accuracy stably with appropriate configuration.

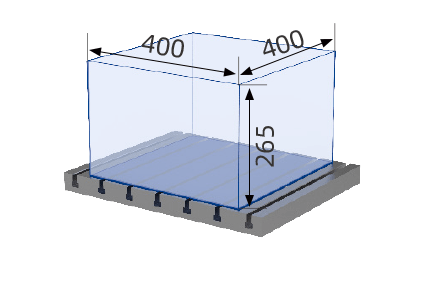

- X/Y/Z Travel: 400/400/200mm

- Worktable Size: 530×430mm

- Max. Load: 300kg

Max. Workpiece Dimension Unit: mm

Max. Workpiece Dimension Unit: mm

- X/Y/Z Travel: 400/400/200mm

- Worktable Size: 530×430mm

- Max. Load: 300kg

JD105E-36-ISO20/F Spindle for Precision Machining

JD135E-32-HE32/F

Highlights

Realize Micron Processing Stably

Appropriate software and hardware configuration to realize 2~5 μm machining precision stably;

Equipped with a 36000rpm precision machining spindle, which is the key component to realize precision machining;

JINGDIAO on-machine inspection system is optional, to quantify the state of machine tools, cutting tools and workpieces in precision machining;

JINGDIAO MQL is optional to meet the cooling requirements of micro milling.

Variety of Optional Configurations to Meet Different Processing Needs

JINGDIAO turntable can be equipped to realize multi-axis machining;

Scraper chip conveyor is available to meet the needs of waste disposal in large cutting quantity processing;

Upgrade to an automatic unit to realize automatic loading and unloading and meet the continuous processing needs of night shift.

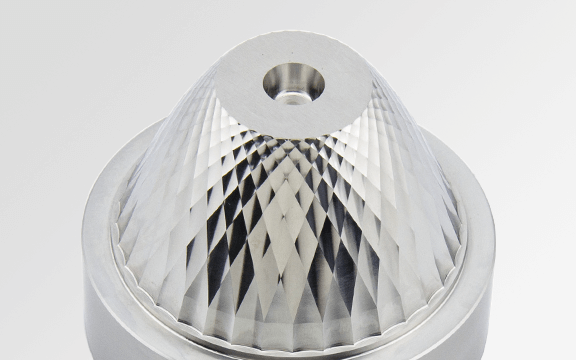

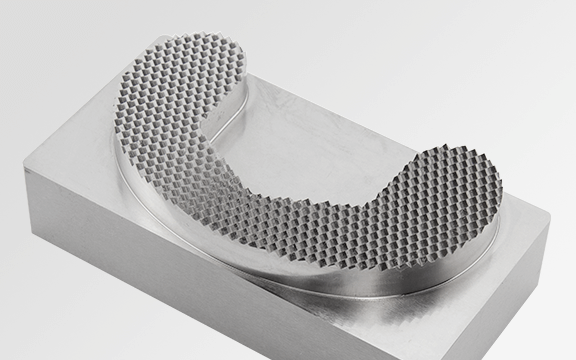

Example Workpiece

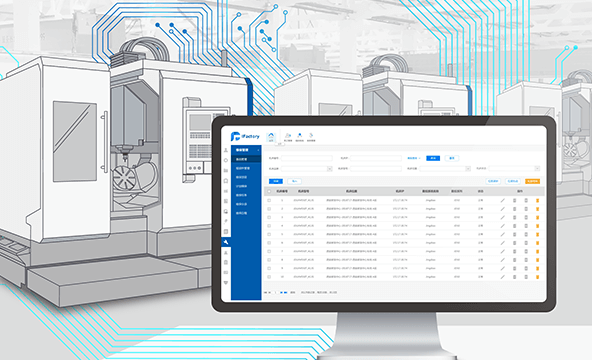

Upgrade to an Automation Unit

HGU400 can deeply integrate JDFMS25 material handling system, upgrade to HGU400 automatic unit, optimize man-machine cooperation mode, ensure the continuity of machine tool production, and provide you with safe, stable and continuous manufacturing experience.

- Storage Capacity: 84/108*

- Maximum load of manipulator (kg): 25

- Maximum workpiece size(mm): 130×120×120

- Loading to unloading time(s): 45

- Weight(kg): 1400

- Air source pressure(Mpa): ≥0.6

- Industrial control system: JMS central control system

- Storage Capacity: 84/108*

- Maximum load of manipulator (kg): 25

- Maximum workpiece size(mm): 130×120×120

- Loading to unloading time(s): 45

- Weight(kg): 1400

- Air source pressure(Mpa): ≥0.6

- Industrial control system: JMS central control system