GRU50

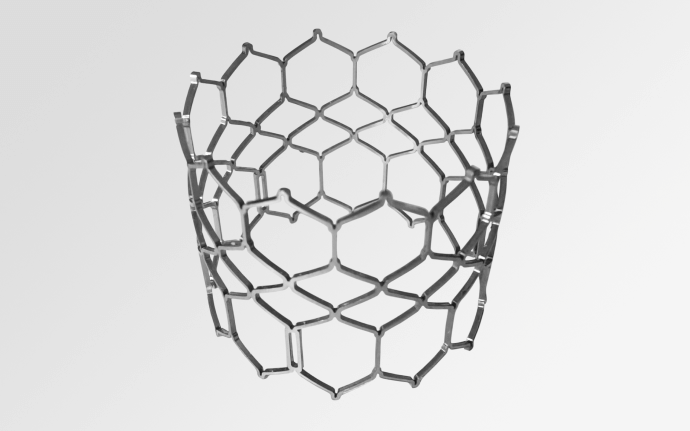

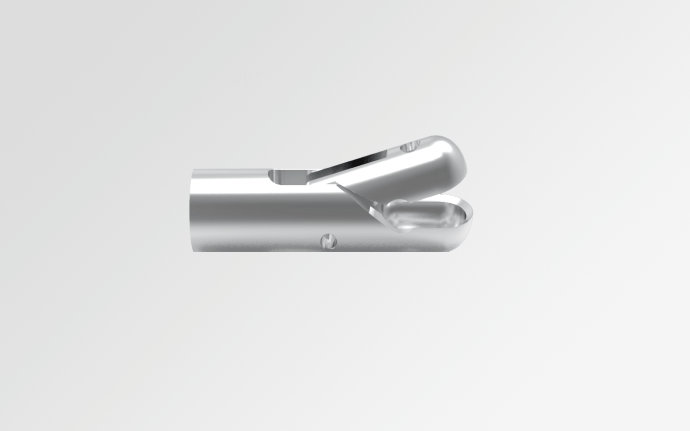

Precision Type JINGDIAO 5-Axis Machining Center not Only Suitable for Precision Machining of Small Products in Medical, Clock, Jewelry and Other Industries, but also for Drilling Small Holes.

The machine weighs 1.65 tons, covers an area of 2.25㎡ which benefits a high space utilization rate.

- X/Y/Z Travel: 235mm/210mm/175mm

- A/C Rotation Range: -15°~125°/360°

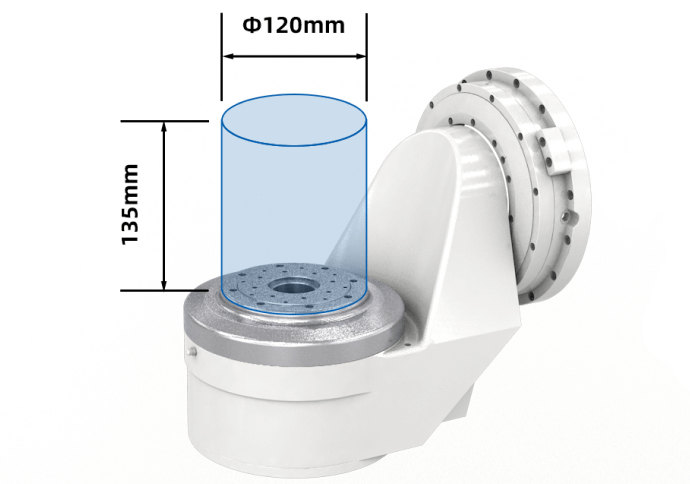

- Worktable Size: Ф110mm

- Max. Load: 10kg

Max. Workpiece Dimension Unit: mm

Max. Workpiece Dimension Unit: mm

- X/Y/Z Travel: 235mm/210mm/175mm

- A/C Rotation Range: -15°~125°/360°

- Worktable Size: Ф110mm

- Max. Load: 10kg

JD105E-36-ISO20/F High-Speed Precision Spindle

JD105E-32-HE32/F

Highlights

High Space Utilization Rate

The machine weighs only 1.65 tons and can be used upstairs;

The machine only covers an area of 2.25㎡ due to compact structure which effectively improves the space utilization rate of the production site.

Stable Processing Quality

Achieve “0.1 μ feed, 1 μ cutting, nanoscale surface roughness” machining stably;

JINGDIAO spindle for precision machining is optional, with a maximum speed of 36000rpm, and can be used for 5-axis micro-hole drilling with a D0.05mm driller;

The capacity of chain type tool magazine is 21 and is perfect for small size parts processing;

Equipped with JINGDIAO on machine inspection system to quantify the status of machine, tools and workpieces in precision machining.

The Advantages on Precious Metal Parts Processing

The three axes of the machine tool are designed with high protection structure, which can effectively prevent waste chips from entering the machine tool;

Stainless steel protective sheet metal is used in the processing area of the machine with a large bevel, which is convenient for waste disposal;

Equipped with an in-machine flushing device to facilitate the flushing and cleaning of precious metal chips;

A recovery filter bag can be installed at the liquid outlet of the machine bed to improve the recovery rate of precious metal chips.