VTE600_DZ

JIGNDIAO CNC Machining Center Suitable for Batch Processing of Metal Parts.

It can stably realize the machining accuracy of 10 ~ 20μm.

Double Z-axis structure, which can realize double processing positions simultaneous processing.

- X/Y/Z Travel: 600/400/330/330mm

- Worktable Size: 830×400mm

- Max. Load: 300kg

-

Spindle Type:

High-Speed Precision Spindle

JD130S-24-BT30/E - Spindle Specification: 24000rpm/BT30

- Tool Magazine: Disc Type(2*24 Tools)

- X/Y/Z Travel: 600/400/330/330mm

- Worktable Size: 830×400mm

- Max. Load: 300kg

-

Spindle Type:

High-Speed Precision Spindle

JD130S-24-BT30/E - Spindle Specification: 24000rpm/BT30

- Tool Magazine: Disc Type(2*24 Tools)

Highlights

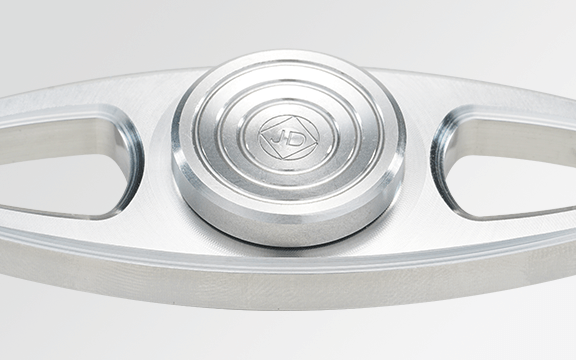

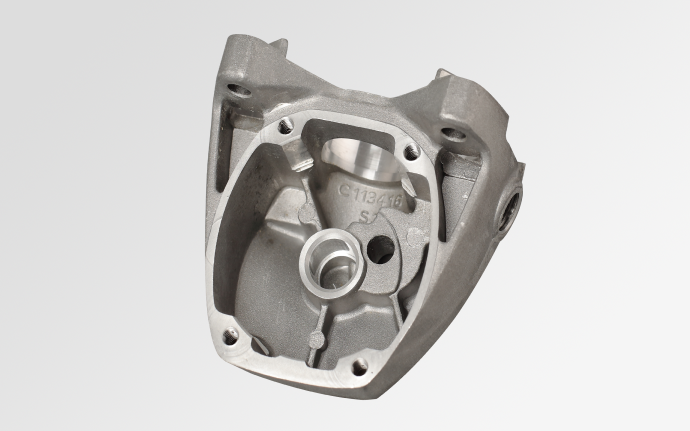

Stable batch processing of parts

It is suitable for batch processing of various 3C products, automobile hardware, etc., and can stably achieve a processing accuracy of 10-20μm;

Equipped with JINGDIAO high-speed precision spindle, which has the features of "low-speed, high-torque, high-speed and low-vibration", it can realize various composite processing such as drilling, boring, tapping, milling, and grinding;

Equipped with a disc-type double tool magazine with 24 tool positions, and chip to chip is only 1.2s.

Select the appropriate software and hardware configuration to ensure the processing quality

Equipped with JINGDIAO on-machine inspection system to quantify the state of machine, tools and workpieces in precision machining;

Optional double processing positions rotary table, to achieve a clamping multi-surface positioning processing.