VTE600

JIGNDIAO CNC Machining Center Suitable for Batch Processing of 3C Structural Parts, Small Hardware Parts, Die Casting Parts and other Product Parts.

It can meet the composite machining requirements of various parts, and can stably realize the machining accuracy of 15 ~ 20μm.

- X/Y/Z Travel: 600/400/340mm

- Worktable Size: 830×400mm

- Max. Load: 300kg

- X/Y/Z Travel: 600/400/340mm

- Worktable Size: 830×400mm

- Max. Load: 300kg

JD150S-20-HA50/C(Standard) Coolant through Spindle

JD150SC-20-HA50/A(Optional)

Highlights

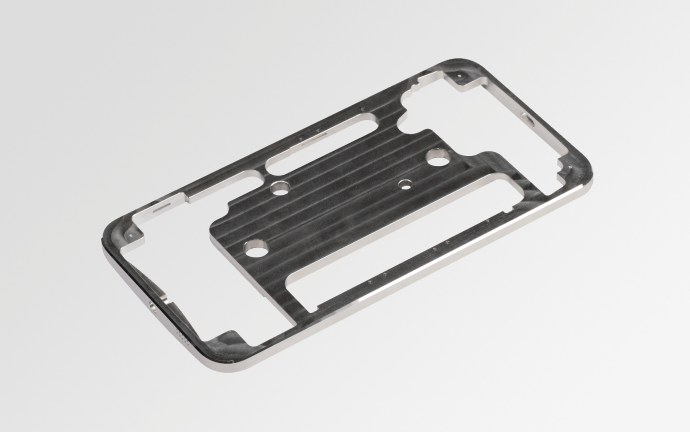

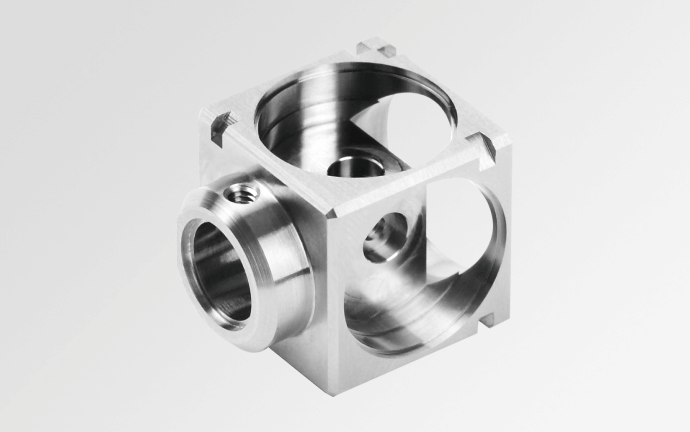

Stable Batch Processing of Metal Parts

Strong composite machining ability, capable of drilling, tapping, grinding, polishing, boring, high-light milling and other processing;

Equipped with JINGDIAO high-speed precision spindle, with strong rigidity and large torque, especially suitable for large-quantity cutting ;

Equipped with internal screw and scraper style chip conveyor, with strong chip disposal capability, which can meet the requirements of large quantity of chip for batch processing;

Equipped with on machine inspection system to quantify the state of machine, tools and workpieces in precision machining.

Choose Appropriate Hardware and Software Configuration to Meet More Production Needs

Equipped with coolant through spindle, using internal cooling tool for deep hole and deep cavity processing;

Equipped with a variety of models of high-accuracy rotary table, expand 3+1 or 3+2 multi-axis processing mode;

The front, left and right side doors can upgrade to automatic doors, which are convenient for automatic production.